The removal of a truck bed is sometimes necessary to perform

certain repairs, such as fuel pump replacement. This task could be performed by

four guys lifting the bed by hand. Not only is this a risky procedure, but

finding available and willing friends to do such dangerous work can be hard to

come by. Motor City Lift King just made a truck bed removal a safe and easy

one-man job.

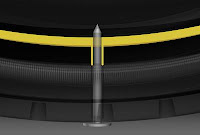

The

patented Lift King requires no power and folds up for easy storage with

measurements of 42” wide, 30”deep and 84”tall. This product is designed to be

used by one person as a fast, easy and safe way to remove/install a pick-up

truck bed, topper, door, and semi hood. The Lift King features a safety system

to protect the product and the operator. Various attachments allow the Lift

King to be utilized for the different jobs and all attachments are switched out

with only a few pins. For more information, visit www.prolinetoolsupply.com.

At Fleetwest, our transferable truck bodies don’t require

you to remove your truck bed. In fact, that’s one of our selling points. Our

steel Load’N’Go and fiberglass composite utility bodies are fully transferable,

even fully loaded, made possible with a no-holes drilled installation. They can

be transferred on and off in minutes with the use of our lifting jacks,

forklift or crane. I’m thinking we may have to give this Lift King a try as

well.

Fleetwest utility truck bodies have more cubic feet of

storage than Bolt-On bodies and have a better return on investment. With the

additional storage, flexibility and efficiency alone, Fleetwest provides fleet

solutions to reduce your operational costs while improving your productivity.

For more information or a detailed quote, call us toll free in the U.S. at

(866) 497-7200 or visit www.fleetwest.net.

Innovative Fleet

Solutions…Transferability Changes Everything!